What Is Plastic Injection Molding Service for?

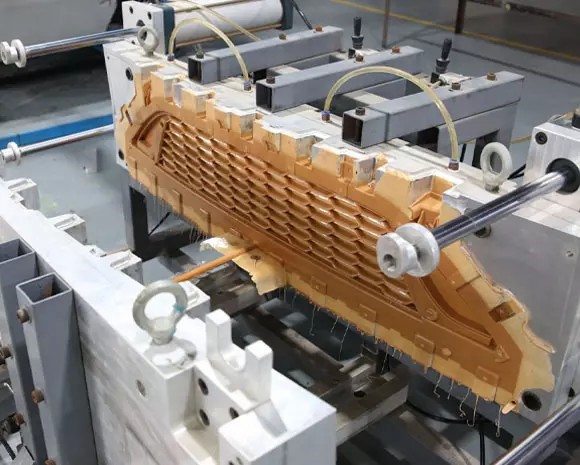

Plastic injection molding is a process that has been around since the late 1800s, but it has only become widely used in the past few decades. This process entails injecting molten plastic into a mold to create a wide variety of plastic products. Injection molding is used to create everything from toys to car parts to medical devices. The process is relatively simple and can be done with a wide variety of materials. In this blog post, we will explore what plastic injection molding service is and its benefits.

What is Plastic Injection Molding Service?

Plastic injection molding is a process by which plastic material is melted and injected by a machine into a mold. The mold can be of any shape or size, and the molten plastic will take on that shape as it cools and hardens. Injection molding is used to create many different types of products, from medical devices to car parts.

This process has several advantages over other methods of manufacturing plastic products. First, it is very versatile and can be used to create products of almost any shape or size. Second, it is fast and efficient, able to produce large quantities of identical products in a short period of time. Finally, injection molded products are very strong and durable, able to withstand high temperatures and pressures.

What Are the benefits of using Plastic Injection Molding Service?

Plastic injection molding is a process that can be used to create a wide variety of parts and products. Injection molding is a versatile manufacturing technique that can be used to produce items from a variety of materials, including metals, plastics, and glass. Injection molding is often used to create parts that are not possible to create using other manufacturing methods.

The benefits of using plastic injection molding services include:

- Increased accuracy: Injection molding produces parts that are more accurate than those produced by other manufacturing methods. This is because the molten plastic is injected into the mold under high pressure, ensuring that the finished product retains the desired shape.

- Cost-effective: Plastic injection molding is a cost-effective manufacturing method, especially when compared to alternative methods. This is because injection molding allows for the mass production of parts at a lower cost per unit.

- Versatile: Injection molding can be used to create parts from a wide variety of materials, including metals, plastics, and glass. This versatility makes injection molding an ideal choice for applications where specific material properties are required.

- Fast: Injection molding is a fast manufacturing process, with most parts taking just minutes to produce. This quick turnaround time means that injection molded parts can be quickly integrated into final products, reducing overall lead times.

Conclusion

Plastic injection molding is a versatile manufacturing process that can be used for a wide variety of products and applications. Whether you need a few hundred parts or millions of parts, plastic injection molding may be the right solution for your project. With so many benefits, it’s no wonder that plastic injection molding is one of the most popular manufacturing processes today. If you are interested in plastic injection molding and want to make the most of it, you can choose KAIAO as your reliable provider because this enterprise promises the accuracy and precision. It will certainly surprise you and boost your business.