Fatigue Life Calculation – An Overview

Fatigue failure is all about the failure of the machine element’s repeated cyclic loading. The cyclic or the repeated loads would be known as the fatigue loads. The fatigue failure occurs due to the fluctuation in the stress. Fatigue life also means the number of stress cycles an element can withstand before the failure would be known as fatigue.

When it comes to checking the material’s fatigue life, there are different tests that are ideally performed. It is understood as that spectrum that gets subjected to the ever-changing tension and compression for the equalised magnitude that gets rotated.

The calculation of fatigue life

you can learn everything about how to calculate fatigue life and everything related to it here.

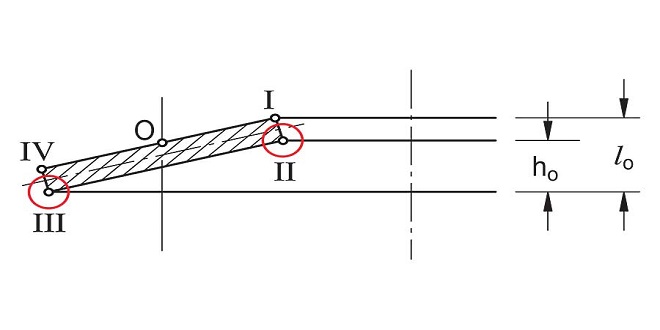

The crack growth rate equation is as follows.

Factor equals the stress minus intensity factor range. A and M are the constants with the function of the environment material frequency stress ratio and temperature.

Different types of fatigue

Once you learn how to calculate fatigue life, You must know different types of fatigue. The fatigue can be grouped under the following.

High-cycle fatigue is all about little or no plastic action. It is stress governed. High-cycle fatigue analysis is performed to understand the endurance limit, a stress level that can be used multiple times without showing any failure. As a thumb rule, the number of cycles 10/5 would be considered as boundary 0.4 low and high cycle fatigue.

Low cycle fatigue

The loading cycles applied in the piping design would typically be pretty for a few 1000. The type of fatigue is identified as low cycle fatigue. The applied stress will normally go beyond the yield strength biology of the material for the low cycle fatigue, which leads to plastic instability in the specimen under test. But when this strain is used as the controllable variable, the results in the low cycle region would be reliable and reproducible.

The characteristics include high loads and a small number of cycles before failure. Here failure occurs only with the stress level in the plastic range, which means significant plastic strange occurs during every cycle. The stresses which cause the fatigue failure in the piping are at peak pressure.

Factors that affect the fatigue behaviour

The factors which affect the fatigue behaviour include the type and nature of loading size of the element and stress or strain distribution besides the service finish and directional properties. It can also mean stress or strain besides environmental effects.

Conclusion:

Hence, calculation of the fatigue life is essential and should be taken seriously. There are multiple approaches which can be used for the same.