All about the spc flooring extrusion line

If you’ve ever been interested in learning about spc flooring extrusion line, here’s a blog that can help! This article will explain the spc flooring extrusion line and why it was created. The blog also talks about the benefits this product offers and other useful information to help you create your project.

What is the spc flooring extrusion line?

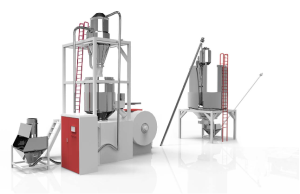

The spc flooring extrusion line is a high-quality production line for the production of flooring products. The extrusion line has a wide range of products that can be produced, including carpets, linoleum, and vinyl flooring. The extrusion line can produce products at high speeds and with high quality.

The spc flooring extrusion line is a new extrusion line that can produce flooring products that are both durable and affordable. It is also versatile, meaning that it can produce products in a variety of different shapes and sizes. This makes the spc flooring extrusion line a great choice for businesses that want to offer their customers a wide range of options.

The spc flooring extrusion line is also easy to use. This means that businesses can quickly and easily create products that fit commercial and residential use. In addition, the spc flooring extrusion line is emissions-free, meaning that it doesn’t produce harmful pollutants.

Benefits of the spc flooring extrusion line

The spc flooring extrusion line is a great option for businesses looking for a durable, affordable flooring solution. Here are some of the benefits of using this line:

-The extrusion line is versatile and can produce various flooring types, including carpet, tile, and hardwood.

-The line is easy to use and has very little downtime.

-The extrusion process is fast and efficient, meaning you can quickly produce a large quantity of flooring.

-The line is sustainable and environmentally friendly, making it a good choice for businesses that want to improve their environmental profile.

How does it work

The spc flooring extrusion line is a great way to finish your flooring project quickly and efficiently. This line can create a variety of different types of flooring, including hardwood, laminate, and tile.

To use this line, you must choose the type of flooring you want to create. Then, you will need to decide on the size and thickness of the sheet you want. Next, you will need to select the type of extrusion machine best for your project. After that, you must load the sheet into the machine and start extruding the flooring.

This line is great for creating high-quality floors quickly and easily. So if you are looking for a quick and easy way to get your flooring project done, this is the line for you.

Conclusion

If you’re interested in learning more about the spc flooring extrusion line, or if you want to learn more about any other types of extrusion lines, be sure to check out our website. We have a wealth of information available on our site, so visit us soon! From simple installation to long-term maintenance, we will take care of everything for you. So why wait? Contact us today and see what our Boyu Extruder can do for your business!

Choosing the right extrusion machine

There are many options in the market for choosing an extrusion machine. If you want to know more about the models currently available and which one might be best for you, read on!

Benefits of an Extruder Machine

Extrusion machines offer benefits that make your printing process more efficient and less time-consuming. If you’re considering purchasing an extrusion machine, here are some of the key advantages to consider:

- Higher throughput – Extrusion machines can produce more products per hour than other printing methods, making them perfect for high-volume production.

- Increased flexibility – With various die types and lengths available, extrusion machines offer greater flexibility when creating customized products.

- Reduced waste – Because extrusion machines produce products continuously, they can reduce the amount of waste produced during printing. This makes them a more environmentally-friendly option when compared to other printing methods.